Validating AVIS Data: Can You Trust What You See?

Collecting data is easy. Knowing you can trust it – that’s where the challenge begins. Automated Vehicle Inspection Systems (AVIS) can capture thousands of measurements and images every day, but those numbers are only useful if they’re reliable. Without validation, even the most sophisticated AVIS risks being ignored or misused.

Why validation matters

Imagine an AVIS reporting a brake pad as worn when it’s fine, or missing a worn wheel entirely. Engineers won’t trust the system, alarms get ignored, and the benefits of automated inspection are lost. Validation ensures the data is accurate, consistent, and meaningful. It’s the foundation of any effective AVIS deployment.

The 3Rs: repeatable, replicable, reproducible

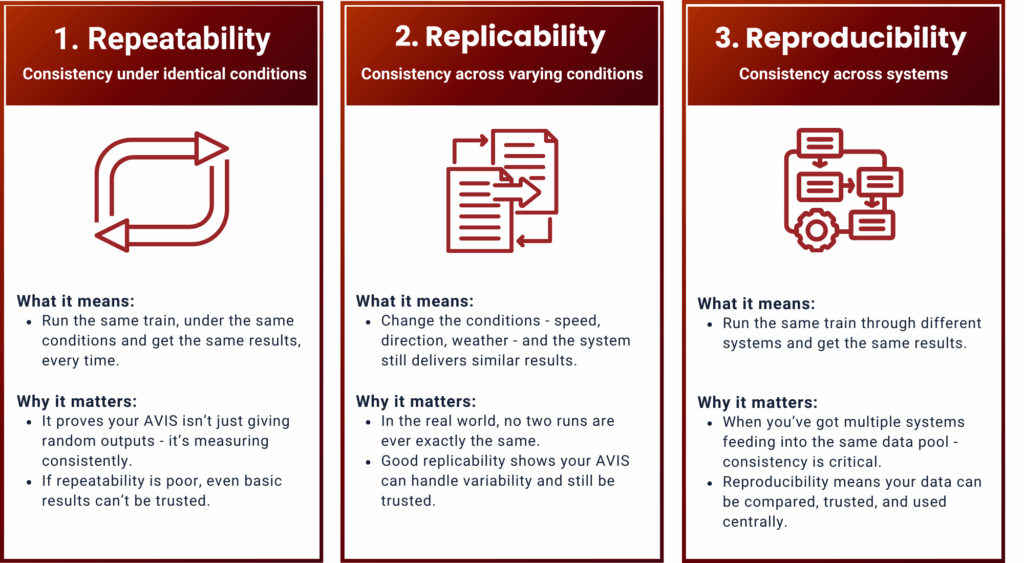

Validation revolves around three core concepts, known as the 3Rs:

- Repeatable: If you measure the same train under the same conditions multiple times, you should get the same result. Repeatability shows that the system is internally consistent.

- Replicable: If you measure the same train under different conditions – different speeds, directions, or weather – the results should still be consistent. Replicability ensures the system can handle real-world variability.

- Reproducible: If you use a different AVIS system to measure the same train, the results should align with the first system. Reproducibility is critical when multiple inspection systems feed data into the same fleet-wide database.

Together, the 3Rs form the backbone of trust in AVIS data.

AVIS validation in practice

Some components are easier to validate than others. For example, checking whether a brake pad is present or missing can be tested with a train deliberately missing a part. More detailed measurements, like brake pad thickness or wheel profile, require careful comparison with traditional methods. AVIS may use different reference points than a steel rule or mini-prof gauge, so the focus should be on consistency over time rather than absolute agreement with old methods.

In some cases, simulated setups can help validate systems, but nothing beats testing under real operational conditions. Establishing baseline figures for repeatability, replicability, and reproducibility gives operators confidence that the system works as intended.

The consequences of poor AVIS validation

Without validation, AVIS risks becoming more of a hindrance than a help. False alarms, missed issues, and inconsistent measurements force staff to double-check everything manually. Trust in the system erodes, and maintenance teams revert to reactive practices — the exact problem AVIS is designed to solve.

Reliable validation ensures that alarms trigger meaningful actions, trends can be interpreted with confidence, and maintenance decisions are based on facts rather than guesswork.

Building a trusted AVIS system

Validation is not a one-time task, it should be part of the lifecycle of every AVIS. Train updates, new modules, or software updates may affect measurements, so repeated validation exercises are essential. The goal is simple: a system where every measurement can be relied upon, and every alert leads to the right action.

Validating AVIS data is the key to turning measurements into insight. Repeatable, replicable, and reproducible data give engineers confidence to act, allowing proactive maintenance, reduced downtime, and safer, more reliable trains. Without it, all the advanced technology in the world is just numbers on a screen.

When AVIS is properly validated, operators can stop asking “Does this work?” and start seeing the benefits every day.