Questions to Ask Before Investing in an AVIS

Automated Vehicle Inspection Systems (AVIS) are often introduced with bold promises: faster inspections, better data, fewer breakdowns. But for many operators, the reality doesn’t match the pitch. Not because the technology is flawed – but because the decision to invest was made without asking the right questions.

Investing in an AVIS is a significant decision – one that deserves careful consideration beyond the technical specs and sales pitch. What are you trying to achieve? How will the system fit into your existing operations? Who will use it, and how will success be measured?

Asking them early sets the foundation for your entire AVIS strategy and can be the difference between a system that transforms your maintenance approach and one that ends up gathering dust. With this in mind, let’s begin by clarifying the specific challenge you want to address.

What are you trying to achieve with AVIS?

It’s easy to get excited about automation. But AVIS isn’t a one-size-fits-all solution. It’s a tool, and like any tool, its value depends entirely on how it’s used.

So before anything else, ask: What problem are we trying to solve?

Are inspections taking too long? Are faults being missed? Is your team stretched too thin? Or are you looking to move towards predictive maintenance and need better data to support it?

The answer will shape everything – from the type of system you choose to how it’s configured and deployed. Without a clear understanding of what you’re trying to achieve, it’s impossible to define success. And without a definition of success, it’s impossible to know whether the investment was worthwhile.

This is where many AVIS projects go wrong. The system is bought because it’s “the future,” not because it solves a specific, identified issue. And when results don’t align with vague expectations, confidence in the system quickly fades.

Will your AVIS integrate with your existing systems?

AVIS doesn’t operate in isolation. It’s part of a wider ecosystem – your maintenance software, your asset management tools, your reporting workflows. If it can’t integrate smoothly, it risks becoming a siloed system that adds complexity rather than clarity.

Integration isn’t just about technical compatibility. It’s about operational fit. Will AVIS data feed directly into your maintenance planning tools? Can it trigger alerts or automatically generate reports?

These are the kinds of questions that need to be asked early, before contracts are signed and installation begins. Because retrofitting integration after the fact is rarely simple and often expensive.

It’s also worth considering future systems. If you’re planning to upgrade your maintenance software or adopt new digital tools, will your AVIS be able to keep up? Scalability and flexibility matter just as much as compatibility.

Is your team ready to use and trust AVIS data?

AVIS generates data. Lots of it. But data alone doesn’t improve safety or reduce downtime. That only happens when the data is understood, trusted, and used.

So ask yourself: Is your team ready?

Do they have the skills to interpret AVIS outputs? Do they understand how the system works and what the measurements mean? Are they confident enough to act on the results and to challenge them when something doesn’t look right?

This isn’t just about training. It’s about mindset. Engineers who’ve spent years relying on visual inspections and manual tools may be sceptical of automated systems. If AVIS results contradict what they see with their own eyes, trust can erode quickly.

That’s why it’s essential to involve your team from the start. Let them help shape the deployment. Give them time to learn the system. Build confidence gradually. Because without their buy-in, even the most advanced AVIS will struggle to deliver value.

How will you measure the success of your AVIS investment?

Every investment needs a return. But with AVIS, that return isn’t always immediate or obvious.

So how will you measure success?

Is it reduced inspection time? Fewer faults missed? Improved safety metrics? Lower maintenance costs?

Whatever your goal, define it up front – not just for internal clarity, but to guide the entire deployment process. If your priority is catching faults earlier, you’ll need a system that can be configured to support anomaly detection and trend analysis. If your focus is streamlining reporting, then integration with your existing maintenance platforms and automated workflows will be key.

The type of AVIS you choose, how it’s set up, and how it’s used day-to-day will all influence how well it delivers on those objectives.

Success also needs to be measurable. That means setting baselines, tracking performance, and reviewing results regularly. AVIS isn’t a “set and forget” system – it’s a living part of your maintenance strategy. And like any part of that strategy, it needs to be monitored and optimised over time.

What will it really cost to keep your AVIS running?

It’s easy to focus on the upfront cost of an AVIS system – the hardware, the installation, the software licence. But that’s just the beginning.

To get the full picture, consider what it takes to keep the system working reliably over time. That includes routine maintenance, calibration, software updates, and long-term support. These aren’t optional extras, they’re essential to ensure the data remains accurate and the system continues to deliver value.

For example, imagine your fleet undergoes a design change – a new brake pad configuration or a modified bogie. That small tweak could mean the AVIS no longer recognises the component correctly. The result? Misread data, missed faults, and a loss of trust in the system. To fix it, you’ll need to recalibrate the module and revalidate the measurements.

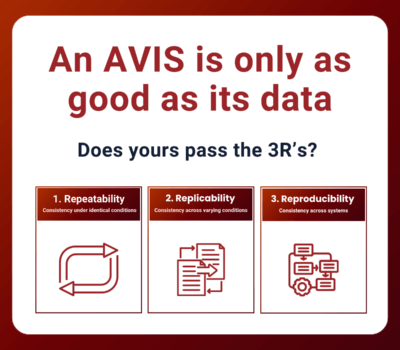

And validation isn’t a one-time job. To maintain confidence in the results, many operators choose to recheck data accuracy annually, especially if the system is used to trigger maintenance actions.

These ongoing tasks require time, expertise, and budget. So when you’re planning your AVIS investment, ask not just “How much does it cost to install?” but “How much does it cost to keep it working, trusted, and useful?”

Next in the Guide: Selecting the Right AVIS for Your Fleet

We’ll explore how to compare systems, assess features, and choose a solution that fits your operational needs.