Getting AVIS Placement Right: Why Location Matters

When it comes to Automated Vehicle Inspection Systems (AVIS), there’s one factor that’s often overlooked – but absolutely critical: location.

You can invest in the most advanced AVIS on the market, with high-spec sensors and powerful analytics. But if it’s installed in the wrong place, it won’t deliver. Missed defects, unreliable data, and frustrated engineers are all symptoms of poor placement. And once confidence in the system is lost, it’s hard to win back.

So why does location matter so much? And what does “getting it right” actually look like?

At the heart of an AVIS is the idea of frequent, consistent data capture. Unlike a wheel lathe, which may give you incredibly detailed measurements but only when a train is booked in, AVIS is designed to monitor conditions over time. It’s about spotting trends – small changes that build up to big problems.

But that only works if the system sees every train regularly.

This is why most AVIS installations are placed at depot entrances or on heavily trafficked routes. If the system is tucked away on a siding or a rarely used road, it becomes an operational headache. Staff have to reroute trains just to get them scanned, and inevitably, some units get missed. The result? Incomplete data, broken trends, and a system that’s no longer doing its job.

How train washing impacts AVIS sensor performance and installation choices

It might seem logical to scan a clean train – after all, dirt can obscure components and affect image quality. But placing AVIS after the wash can introduce a new problem: water.

Optical modules don’t like moisture. Droplets on lenses or reflective surfaces can distort readings or block measurements entirely. That’s why, in most cases, it’s better to install AVIS before the wash. You’ll still get a reasonably clean train, but without the risk of water interfering with the sensors.

Of course, this depends on the module type. Some systems do benefit from a cleaner surface, especially when measuring fine detail. But even then, the wash process needs to be carefully managed to avoid compromising the equipment.

How weather and track conditions impact AVIS performance

Most AVIS systems are designed to work outdoors. But that doesn’t mean they’re immune to the elements.

Direct sunlight can cause glare, throwing off optical readings. Rain can fog lenses or seep into sensitive components. Leaves, dust, and oil can build up on track-mounted modules, blocking sensors or causing misreads.

These issues don’t just affect accuracy – they can shorten the lifespan of the equipment and increase maintenance costs. That’s why shielding is so important. Whether it’s a canopy, drainage system, or regular cleaning schedule, protecting your AVIS from environmental exposure is a smart investment.

How train movement affects AVIS measurements and reliability

AVIS systems rely on trains moving through them in a predictable way. The speed, direction, and continuity of movement all help the system assign measurements to the correct part of the train.

But what happens when a train stops over the system? Or rolls back slightly?

Suddenly, the logic breaks down. The system can’t be sure which components it’s scanned, or where they were located. In some cases, it may have to discard the data entirely to avoid misassigning it. And if the train sits too long, optical modules may time out and close their shutters, missing everything that comes after.

That’s why placement should prioritise smooth, continuous movement. Avoid locations where trains frequently stop, idle, or reverse. The more predictable the flow, the more reliable the data.

How overlooked site factors can undermine AVIS accuracy and reliability

Beyond the obvious factors – traffic frequency, wash location, weather exposure – there are subtler issues that can sabotage an AVIS installation.

Poor lighting can affect image clarity. Incorrect mounting angles can distort measurements. Vibrations from nearby equipment or uneven track can throw off sensor alignment. These aren’t always considered during planning, but they can have a big impact on performance.

That’s why AVIS design should be a collaborative process. Engineers, depot managers, and system vendors need to be involved. Walk the site. Test the conditions. Think about how trains move, how the environment behaves, and how the system will be maintained.

Because once the AVIS is installed, fixing a poor location isn’t easy, or cheap.

How thoughtful AVIS design and site planning drive long-term success

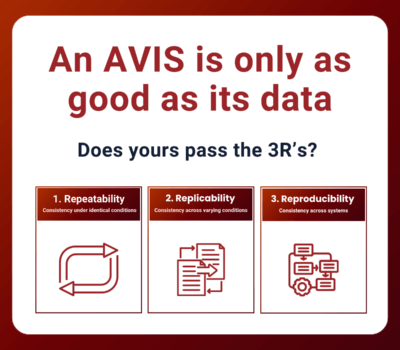

An AVIS is only as good as its setup. And setup starts with location.

Before you commit to installation, take the time to get the design right. Think about traffic flow, environmental risks, operational routines, and long-term maintenance. Ask the hard questions now, because once the system is in place, it needs to work.

When AVIS is installed thoughtfully, it becomes a powerful tool for safety, reliability, and efficiency. When it’s not, it becomes a source of frustration.