Automated Vehicle Inspection Systems (AVIS) for trains: Finding the right solution for your fleet

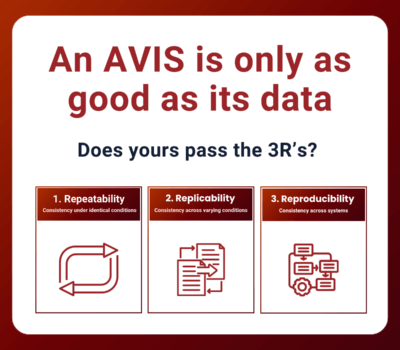

Automated Vehicle Inspection Systems (AVIS) are becoming essential tools for Rolling Stock Companies (ROSCOs) and train operating companies (TOCs) seeking to enhance the safety, efficiency and maintenance of their trains. Automated Vehicle Inspection Systems use advanced technologies to streamline inspections, providing quicker and more accurate assessments compared to traditional manual methods.

The challenge lies in selecting the right inspection system that meets their fleet’s specific needs. This article provides an overview of the available options and highlights how they can benefit your operations.

Depot-based automated vehicle inspection systems

A depot-based AVIS is an ideal solution for routine inspections carried out when trains come in for servicing. These systems are integrated into the depot and perform key checks on various components as the train passes through. Key areas inspected include wheels, brakes, pantographs and underframe features.

One of the key benefits of a depot-based system is its ability to automate tasks that are traditionally time-consuming, such as wheel profile measurement, brake pad wear and bogie condition monitoring. These systems often use high-definition cameras, laser technology and sensors to detect any signs of wear or damage. The detailed data provided by these systems allows for predictive maintenance, optimised downtime and faster detection of in-service failures.

For large or complex fleets, a depot-based inspection system can save significant time and resources, while improving overall safety. This is especially useful when combined with a comprehensive maintenance strategy that ensures any identified issues are addressed promptly.

It is important to note that most depot-based inspection systems are designed for one or two specific fleets. They are a significant investment and adapting them for use with different fleets requires extensive modifications or replacement to function, making them best suited for situations where a fleet will be stationed at the location for an extended period.

Fleet-specific modules

When considering AVIS options, ROSCOs and TOCs need to look at which inspection modules are most relevant to their specific fleet. Different fleets have unique requirements based on their design and operational demands.

For example, Electric Multiple Units (EMUs) may benefit from an inspection system that includes the pantograph to measure the wear of the carbon strips or train shoe collector to measure the condition of the collector shoes.

Newer fleets may feature onboard axle temperature monitoring, while older fleets could benefit from axle heat detection systems. Freight wagons may require enhanced inspections of axles and bearings, whereas passenger trains often have multiple underframe components that can be scanned for damage.

On-track inspection systems

In addition to depot-based systems, on-track inspection systems offer real-time monitoring of trains while they are in service. These systems use sensors and cameras installed along the track to inspect trains as they pass by. On-track inspections are usually installed by Network Rail to identify faults that require immediate action, such as pantograph defects or overheating axles, that can be addressed before they lead to major problems.

Where on-track system data is available, it can offer valuable insights, facilitating predictive maintenance and optimisation without the need for a dedicated depot system. While on-track systems may not provide the same level of detail or customisation as dedicated systems, they represent an often-overlooked resource that is worth exploring.

Choosing the right automated vehicle inspection system

ROSCOs need to consider several factors when deciding which AVIS is right for their needs. For example, a depot-based system may be best suited for TOCs that have a long period to run with a particular fleet at a location and scope for significant savings and/or safety improvements. Whereas utilising existing on-track systems may provide some benefits where the cost of a dedicated system can not be justified.

Additionally, TOCs with an interest in predictive maintenance will find that integrating AVIS into their broader maintenance strategy helps extend component life-times, identifying outliers and improving overall fleet performance.

How We Can Help

Ensuring a successful rollout of an automated inspection solution can be overwhelming, but we’re here to help. With our technical expertise in automated vehicle inspection systems, we can guide you through the process of selecting and implementing the best system for your fleet’s unique requirements.

Whether you need a customised depot-based solution, utilisation of on-track monitoring or integration of these systems into your current operations systems, we offer expert advice and support to ensure your AVIS delivers maximum value for your operations. Get in touch to find out how we can help you.