The solution

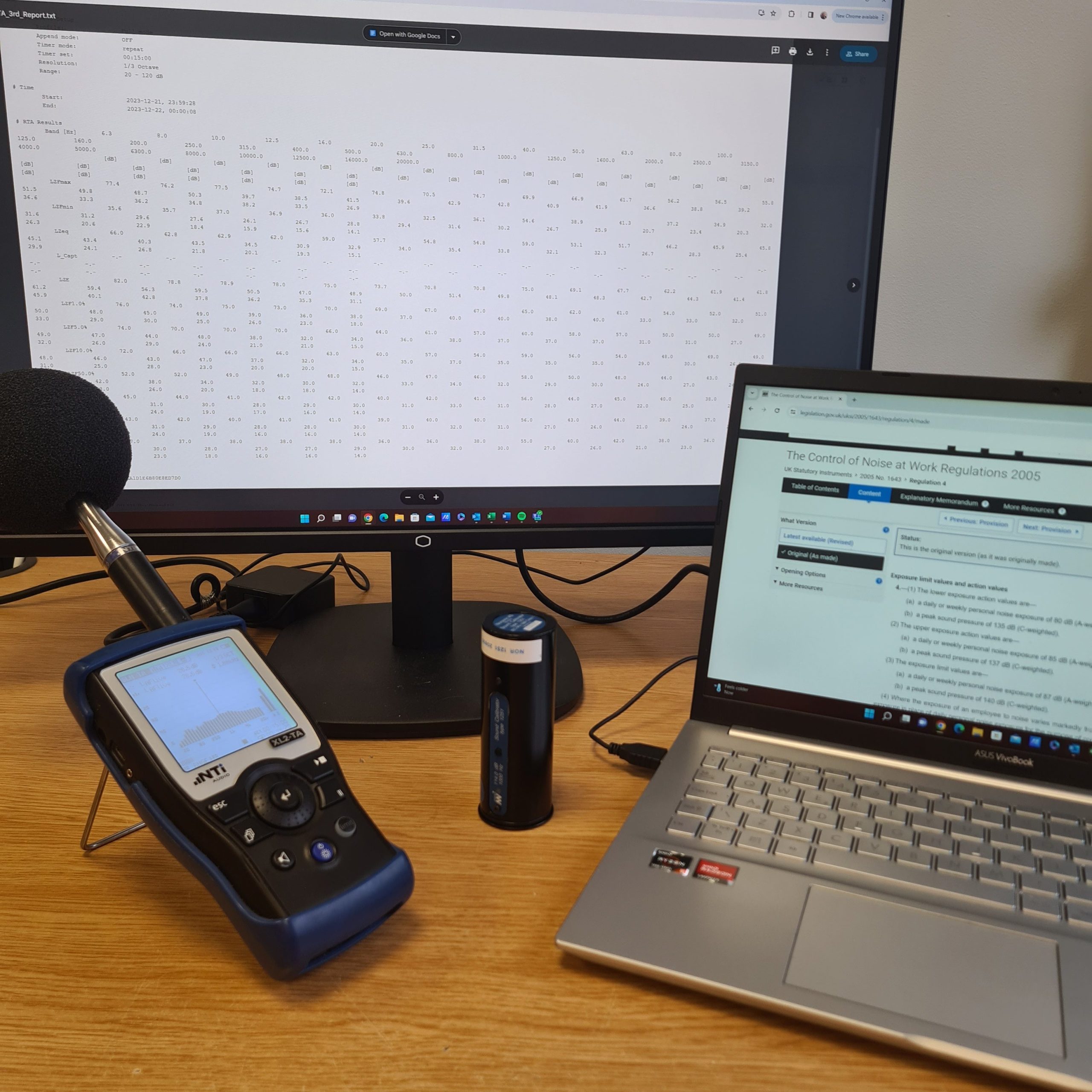

To gain an in-depth understanding of the situation, the Encompass team conducted a thorough GEMBA walk in these areas, giving us a first-hand view of operations and an opportunity to uncover potential challenges and opportunities.

By visiting the storage area for tools and observing their usage, we collected valuable data to assist in addressing the issues and allow us to propose solutions that could help move operations forward in a more productive way.

We not only observed the storage, utilisation, and management of tools, but we also spoke directly with individuals using the tools to gain deeper insights into the processes.

Our examination included their workflows, storage methods, tracking mechanisms, and overall tool management practices, as well as considering broader factors such as health and safety constraints and the cleanliness of the depot.

Following our review, we compiled a detailed report outlining the key issues and presenting several solutions to address their current challenges. These recommendations included ‘quick wins’ that WMT could implement using the existing resources they had already available to more long-term solutions, such as cultural change management initiatives and solutions that involved investment in additional materials and storage devices.