Practical ways to achieve sustainable train maintenance

With rail travel rivalling road and air transport as a greener alternative to travel, it’s easy to focus on the big-picture sustainability wins – electrified networks, energy-efficient trains and reduced emissions. But a less glamorous, often overlooked side to this is how we maintain those trains.

Maintenance might not be the headline act, but it’s centre stage when looking for ways to reduce waste, cut carbon and extend the life of valuable assets. Done right – sustainable maintenance is a quiet powerhouse – improving efficiency, lowering costs and helping rail operators meet ambitious environmental targets.

So, what does this look like in practice?

What is sustainable train maintenance?

Sustainable train maintenance involves looking after trains and other rail vehicles in ways that reduce harm to the environment. It’s about doing routine maintenance, repairs and overhauls in a way that uses fewer resources, produces less waste and less emissions. These practices help train operators save money, improve the lifespan of their equipment and contribute to a more sustainable future for rail transport.

Rethinking the depot: energy use with purpose

Maintenance depots consume significant energy, but operators can lower their carbon footprint by implementing sustainable practices. Many depots are now integrating renewable energy sources, such as motion-sensor-activated LED lighting, intelligent heating and cooling systems, and centralised energy management platforms that allow for more precise control over energy consumption throughout the depot. Additionally, standby modes for maintenance equipment and more efficient train stabling processes contribute to energy conservation. Whilst this transition to more renewable energy sources and greener technologies requires investment upfront, the long-term benefits from these upgrades can reduce costs over multiple years.

Environmentally-friendly cleaning and lubrication

Cleaning trains is essential but often comes with an environmental cost. Traditional cleaning methods rely on harsh chemicals and excessive water use. Switching to biodegradable cleaning agents and adding a water recycling system can cut water use by half and reduce your chemical footprint without compromising cleanliness.

The same logic applies to lubricants. Choosing bio-based oils over synthetic ones means less risk to local waterways if there’s a spill, and is a good example that even small changes can support a healthier environment.

Recycling and reusing parts

A key principle of sustainable maintenance is extending the lifespan of train components through refurbishment and reuse. Instead of discarding parts – repurpose and reuse interchangeable components within similar fleets, such as brake controllers and passenger-facing parts. This practice reduces the need for new materials and the energy consumption and emissions associated with manufacturing new components.

Predictive maintenance with smart technology

Predictive maintenance is transforming the efficiency of train upkeep. By using sensors and data analytics, maintenance teams can monitor train conditions in real-time, anticipating failures before they occur. This technology helps prevent costly breakdowns, reduce unnecessary inspections, and optimise resource allocation for a more streamlined approach.

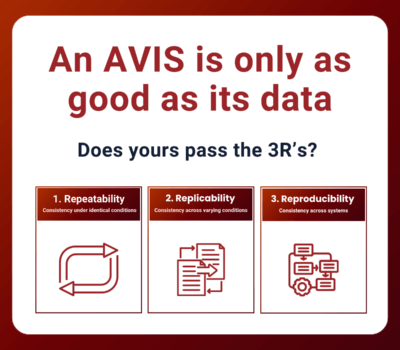

A key aspect of predictive maintenance is the effective integration of automated vehicle inspection systems or AVIS. These systems provide real-time feedback on fleet conditions, enabling more accurate and efficient maintenance scheduling. At Encompass Engineering, we assist with assessing depot suitability for these systems, ensuring proper placement and seamless integration into daily operations. We also help with system integration, staff training, and configuration to ensure the equipment operates efficiently and enhances safety.

Alternative fuels for maintenance vehicles

Maintenance depots often rely on diesel-powered service vehicles, contributing to air pollution. However, many operators are now using alternative fuels, such as biodiesel and hydrogen, and even adopting electric vehicles for depot operations. These cleaner, more renewable fuels significantly reduce carbon emissions and often provide a two-fold benefit. For example, using electric vehicles results in zero-emissions and reduced noise pollution during depot activity.

Waste reduction and management

A robust waste management strategy is crucial for minimising environmental impact. Many depots now implement comprehensive recycling programs for oil, plastic and metal, while hazardous waste, such as batteries and electrical components, is disposed of responsibly.

Additionally, a growing trend is the implementation of zero-waste-to-landfill policies. These policies convert non-recyclable waste into energy through waste-to-energy processes, such as gasification and pyrolysis. These processes burn the waste at very high temperatures and convert it into gas for fuel or oil and charcoal-like materials rather than incinerating it. Waste that can be recycled is sent to recycling centres that recover reusable materials and reduce the costs involved in typical waste management processes.

Small changes, big impact

Sustainable train maintenance doesn’t have to be radical. It’s about looking at what you already do and asking: how can we do this better – for the planet, for our people, and for our bottom line?

Whether it’s cutting energy use, switching to greener products, or making the most of your existing assets, small changes add up. And when more operators embrace these approaches, the impact is real – across the industry and beyond.

Ready to get started?

If you’re looking for ways to make your train maintenance practices more sustainable – or simply more efficient – we’re here to help. From smarter monitoring to practical advice – we can help you build greener, more cost-effective operations.